GMN SPINDLE PRODUCTS AND APPLICATIONS

GMN SPINDLE PRODUCTS AND APPLICATIONS

WE OFFER THE BEST SOLUTION FOR YOUR APPLICATION

GMN is known for producing high-precision spindles that are widely used in various industries, including aerospace, automotive, food and beverage, and medical technology. For more information on industries, visit our industries page.

GMN is recognized for its precision engineering and manufacturing capabilities. Spindles are designed and built to meet high standards of accuracy, reliability, and performance.

OD: 80-400 mm

SPEED: max. 250,000 rpm

POWER: max. 36 kW (S1)

TORQUE: 1,000+ Nm (S1)

MOTOR: A-/Synchronous

TOOL TYPE: Thread Pilot, HSK-C

LUBRICATION: Oil-air / Perm. Grease

TOOL CHANGE: Manual / Automatic

OD: 80-380 mm

SPEED: max. 90,000 rpm

POWER: max. 150 kW (S1)

TORQUE: max. 1,005 Nm (S1)

MOTOR: A-/Synchronous

TOOL TYPE: HSK, SK, BT, C, KM4X

LUBRICATION: Oil-air / Perm. Grease

TOOL CHANGE: Manual / Automatic

- OD: Customer’s Spec

SPEED: max. 250,000 rpm

POWER: max. 350 kW (S1)

TORQUE: max. 1,750 Nm (S1)

MOTOR: A-/Synchronous

TOOL TYPE: Customer’s Spec

LUBRICATION: Oil-air / Perm. Grease

TOOL CHANGE: Manual / Automatic.

MANUAL TOOL CHANGE SPACE

OD: 80-170 mm

SPEED: max. 250,000 rpm

POWER: max. 36 KW (S1)

TORQUE: max. 26 Nm (S1)

MOTOR: A-/Synchronous

TOOL TYPE: Thread Pilot, HSK-C

LUBRICATION: Oil-air / Perm. Grease

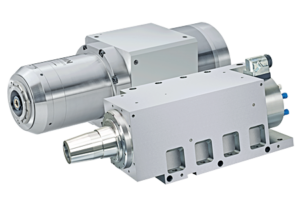

AUTOMATIC TOOL CHANGE

OD: 80-170 mm

SPEED: max. 250,000 rpm

POWER: max. 36 KW (S1)

TORQUE: max. 26 Nm (S1)

MOTOR: A-/Synchronous

TOOL TYPE: Thread Pilot, HSK-C

LUBRICATION: Oil-air / Perm. Grease

CUSTOM ENGINEERED SPACE

OD: 80-170 mm

SPEED: max. 250,000 rpm

POWER: max. 36 KW (S1)

TORQUE: max. 26 Nm (S1)

MOTOR: A-/Synchronous

TOOL TYPE: Thread Pilot, HSK-C

LUBRICATION: Oil-air / Perm. Grease

INNOVATIVE SOLUTIONS FOR ALL CUSTOMER NEEDS

From high speed grinding to high power milling applications, GMN has the solution for all your machining needs. In addition to a comprehensive range of standard spindle types, GMN will also design and develop special spindles to meet the specific requirements of our customers.

GMN is a market leader for spindle technology worldwide, especially in the field of innovative solutions for precision and high speed machining.

INNOVATIVE SOLUTIONS FOR ALL CUSTOMER NEEDS

From high speed grinding to high power milling applications, GMN has the solution for all your machining needs. In addition to a comprehensive range of standard spindle types, GMN will also design and develop special spindles to meet the specific requirements of our customers.

GMN is a market leader for spindle technology worldwide, especially in the field of innovative solutions for precision and high speed machining.

HIGH PERFORMANCE ELECTRIC MOTORS

GMN high-speed electric motor characteristics include high power density, compact, robust, precision design and highly balanced. These characteristics provide superior product quality and optimum reliability. Using its broad range of complete motors, insert elements and custom solutions, GMN is able to make high operating speeds usable for a large number of customer applications.

HIGH PERFORMANCE ELECTRIC MOTORS

GMN high-speed electric motor characteristics include high power density, compact, robust, precision design and high quality balancing. These characteristics provide superior product quality and optimum reliability. Using its broad range of complete motors, insert elements and custom solutions, GMN is able to make high operating speeds usable for a large number of customer applications.